We specialize in providing highly acclaimed silk screen printing services for our clients who need publicity like offices, various institutes, corporates, fashion houses and many more. These prints are created strictly as per the specific requirements of our prestigious customers.

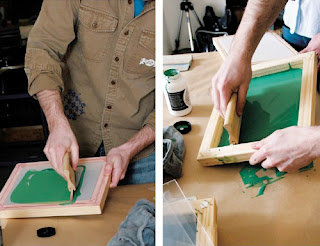

We specialize in providing highly acclaimed silk screen printing services for our clients who need publicity like offices, various institutes, corporates, fashion houses and many more. These prints are created strictly as per the specific requirements of our prestigious customers. Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A roller or squeegee is moved across the screen stencil, forcing or pumping ink past the threads of the woven mesh in the open areas.

Screen printing is a printing technique that uses a woven mesh to support an ink-blocking stencil. The attached stencil forms open areas of mesh that transfer ink or other printable materials which can be pressed through the mesh as a sharp-edged image onto a substrate. A roller or squeegee is moved across the screen stencil, forcing or pumping ink past the threads of the woven mesh in the open areas.Screen printing is also a stencil method of print making in which a design is imposed on a screen of silk or other fine mesh, with blank areas coated with an impermeable substance, and ink is forced through the mesh onto the printing surface. It is also known as silkscreen, serigraphy, and serigraph printing.

A heat press is a machine engineered to imprint a design or graphic on a substrate, such as a t-shirt, with the application of heat and pressure for a preset period of time. While heat presses are often used to apply designs to fabrics, they can also be used to imprint designs on mugs, plates, jigsaw puzzles, and other products.

Both manual and automatic heat presses are widely available. A new style of press that is semi-automatic has entered the market as well, allowing for a manual closing process with an automatic opening. Digital technology in newer machines enables precise control of heat and pressure levels and timing. The most common types of heat press employ a flat platen to apply heat and pressure to the substrate. In the "clamshell" design, the upper heat element in the press opens like a clamshell, while in the "swing-away" design, the heat platen swings away from the lower platen. Another design type a "draw style press" allows for the bottom platen to be pulled out like a drawer away from the heat for preparation of the graphic. Vacuum presses utilise air pressure to provide the necessary force and can achieve high psi ratings.Most heat presses currently on the market use an aluminum upper-heating element with a heat rod cast into the aluminum or a heating wire attached to the element. For high-volume operations involving the continuous imprinting of items, automatic shuttle transfer presses are used. The substrates to be imprinted are continuously loaded onto the lower platen and shuttled under the heat platen, which then applies the necessary heat and pressure.

The pattern is printed in sublimating ink on sublimating paper which allows the pattern to transfer. You can get some highly effective patterns and great effects using this technique.

3.Embroidery

Embroidery is the art or handicraft of decorating fabric or other materials with needle and thread or yarn. Embroidery may also incorporate other materials such as metal strips, pearls, beads, quills, and sequins. Embroidery is most often recommended for caps, hats, coats, blankets, dress shirts, denim, stockings, and golf shirts. Embroidery is available with a wide variety of thread or yarn color.

Embroidery is the art or handicraft of decorating fabric or other materials with needle and thread or yarn. Embroidery may also incorporate other materials such as metal strips, pearls, beads, quills, and sequins. Embroidery is most often recommended for caps, hats, coats, blankets, dress shirts, denim, stockings, and golf shirts. Embroidery is available with a wide variety of thread or yarn color.A characteristic of embroidery is that the basic techniques or stitches of the earliest work—chain stitch, buttonhole or blanket stitch, running stitch, satin stitch, cross stitch—remain the fundamental techniques of hand embroidery today.

Machine embroidery, arising in the early stages of the Industrial Revolution, mimics hand embroidery, especially in the use of chain stitches, but the "satin stitch" and hemming stitches of machine work rely on the use of multiple threads and resemble hand work in their appearance, not their construction.